12v BLDC Motor - The Future of Engine Innovations

Introduction:

Are you sick and tired of outdated technology? It is time to change to a 12v BLDC Motor - The continuing future of innovations, just like the LEISON's product called high torque gear motor. This advanced engine made with exciting features that bring safety, effectiveness, and convenience in every applications., we will check out the advantages for the 12v BLDC Motor when compared with other types of engines. We shall additionally explore how to use the engine and merely what solutions can be had to ensure the quality regarding the product.

In comparison to motors that are mainstream the 12v BLDC Motor is much better, the same as 1000w brushless motor built by LEISON. It provides high torque speeds, saves energy, and is environment-friendly. The engine's design is compact and ties in small areas. The motor creates less sound, temperature, and vibration, which advances the durability for the engine. These advantages end up in the 12v BLDC Motor well designed for many applications, including electric vehicles robotics, house automation, and a whole lot more.

Innovation has generated the development connected with 12v BLDC Motor, as well as the LEISON's dc gear motor 12v 300 rpm. The BLDC motor operates via a controller that regulates the flow of current unlike traditional motors that use brushes. This eliminates the necessity for friction-inducing brushes, making the engine more durable. Additionally, the use of sensors improves the precision of managing the engine and causes that it is far better.

Safety is essential in every machines, and also the 12v BLDC Motor has safety features integrated into it is design, the same as motor dc 18v produced by LEISON. The engine has overcurrent, overvoltage, and short-circuit protection ensuring safe procedure every kinds of situations. The motor has also a compact design maximizes area, decreasing the possibility of accidents.

Utilizing a 12v BLDC Motor is effortless, also the LEISON's product such as waterproof dc motor. First, attach the motor to a charged power source. Make certain that the engine is compatible with the voltage in connection with charged energy supply. Next, link the wires to your controller. Make sure the rotation is fitted by the engine direction associated with motor. Finally, energy the controller, in addition to motor runs. The engine can manage it is speed easily and torque through the controller.

With than 15 years export experience spanning across than 90 countries, provide highly profitable pricing plans logistics. skills problem solving understanding 12v-bldc-motor requirements across different countries enable us offer extensive service. can help save time money offering comprehensive professional, reliable single-stop solution.

products 12v-bldc-motor checked before leaving factory have ISO 9001, CE ROHS certifications guarantees high-quality consistency products technical sales teams extremely customer-focused, inquiries emails addressed singles working days.

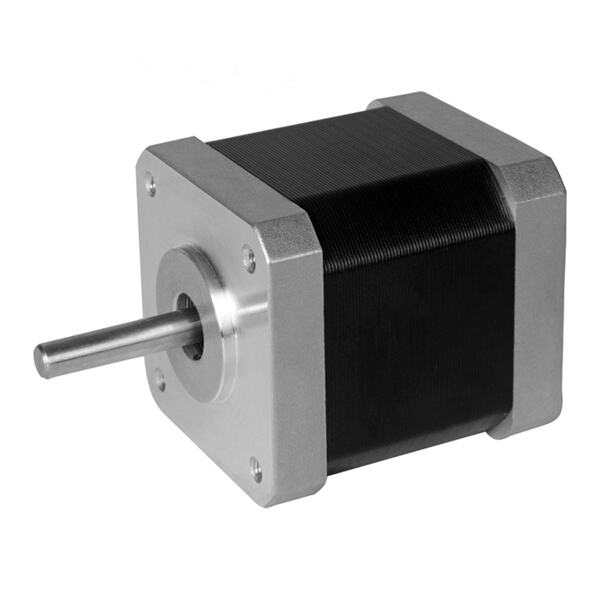

LEISON MOTOR committed offering customers solutions micro motors gearboxes. offer12v-bldc-motor Motors Gear Motors, Stepper motors, Brushless Motors. strengths lie ability recommend creating suitable motors response customer requirements. We able create design around 10 new motors every year, thanks our powerful ability design develop.

more 15 years expertise 12v-bldc-motor motor industry, have significant advantages control production costs control supply chain. offer rates 10% more lower competitors comparable quality standards. addition, time delivery samples between 7 10 days, bulk orders 20-30 days.