Top Gear Motors Within the United States of America for Your Requirements

Introduction:

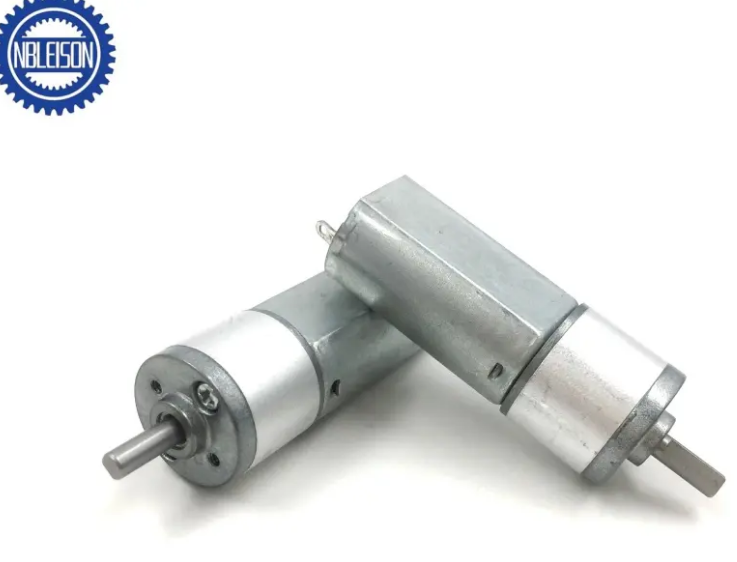

The next step that may pose a challenge when you are searching for the right gear motor is presented below. Fortunately, today there are numerous vendors operating in the United States of America to provide you the quality, safety as well as the innovation that is required. It is now time to paying more attention to the recommended best selling gear motor to use from LEISON.

Advantages of Gear Motors:

With other types of motors several advantages of gear motors include that gear motors can deliver high torque while at lower speed. They are also very rugged making them suitable to be used in many areas such as core manufacturing and robotics automotive, aerospace and much more. Further, the gear motors are more efficient than the other motors, which helps to save energy as well as improve the sustainability aspect.

Innovations in Gear Motor Technology:

Although gear motors are quite traditional in many ways, the technology has seen some thrilling advancements in the previous years. One of the innovations distinguishable is presence of brushless DC gear motors; it has a high efficiency, longer expected life cycle, and enhanced precision as opposed to brushed motors. Some such innovations are variable speed drives that control the speed of the motor, and integrated controls that make installation and use much easier.

Safety Considerations:

When choosing a gear motor to make a purchase, safety aspects should stand out especially. When selecting a gear motor, you should consider looking at the sturdiness of the components that make up the gear motor; additional aspects such as the incorporation of overload protectors or integral thermal switches. Furthermore, check the motor to ensure you select the correct right one for the given application and use it in accordance with the manufacturer’s recommendations.

Using Gear Motors:

Employing a gear motor is quite simple; however, there are some important factors that need to be taken into account. First, there must be a check to confirm that the motor is well fixed to offer support to the rest of the apparatus. Subsequently, solder the electric gear motor with the help of a power source and to any other part if necessary. Last but not lease, forward the motor to check if it is functioning properly.

Servicing Gear Motors:

Maintenance and service plays crucial part of operation and longevity of your gear motor that’s why it must be done on regular basis. This may entail activities such power wash, greasing and changing worn out parts such as the engine oil. It is also vital to adhere to the manufacturer’s recommendations regarding maintenance and make sure to get your vehicle to the service for a check-up even if there are no apparent problems.

Quality and Application:

The major thing prior to going for the gear motor will be the quality of the gear motor. Ensure that motors are of top quality, and are produced by conforming to the highest production standards. Also, note the operational description of the application that the motor will be part of and select a motor that will provide the necessary torque and speeds. In a manufacturing plant, gear motor may be used in a robot or another device; to be certain that the motor will work efficiently, it is recommended that one gets a quality motor.

En

En

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

BN

BN